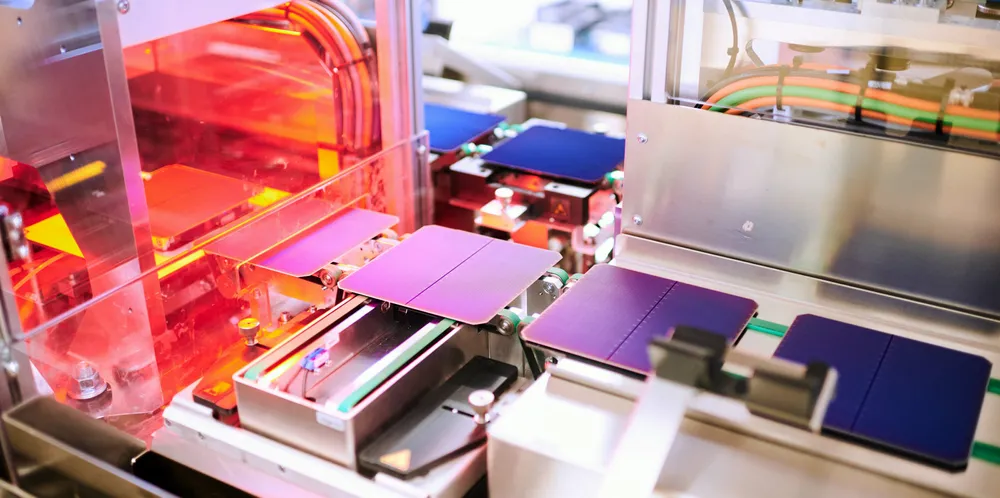

Meyer Burger eyes mass production of 'record-efficiency' solar cells

Swiss manufacturer signs cooperation deals with top research bodies to propel high-yield perovskite tandem PV cells from laboratory to industrialisation

Meyer Burger has established a new partnership with a consortium of high-profile research institutions with the aim to produce solar cells with efficiencies of more than 30% on an industrial scale.

To get perovskite tandem technology with super-high yields ready for mass production, the Swiss solar panel maker has signed multi-year cooperation agreements with CSEM from Switzerland, Helmholtz-Zentrum Berlin (HZB), the Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, Germany, and the Institute of Photovoltaics at the University of Stuttgart.

HZB has already achieved record efficiencies in excess of 31% for laboratory tandem solar cells in combination with heterojunction and perovskite, but so far only in a research environment.

“Meyer Burger has an extensive portfolio of processes, technologies, and production techniques at its disposal for the potential mass production of tandem solar cells and modules in-house,” says Marcel König, head of research and development at Meyer Burger.

“This includes the essential manufacturing processes and machinery for silicon-based perovskite tandem solar cells, as well as corresponding solar modules with Meyer Burger’s proprietary SmartWire connection technology.”

The company also has a research collaboration for perovskite technology with Oxford PV, and with CSEM already has achieved a record efficiency of 29.6% for a 25-square-centimeter perovskite tandem solar cell through combining heterojunction silicon cells with perovskite structures.

“This outstanding result demonstrates the potential of silicon perovskite tandem cells to achieve high efficiencies,” said CSEM sustainable energy director Christophe Ballif.

“Although we still have a lot of work ahead of us, the industrialisation of solar cells with an efficiency of over 30% is on the right track.”

Fraunhofer ISE director Andreas Bett added: “The aim is for perovskite/silicon modules to meet the high standards of reliability and longevity set by classical silicon PV technology.

“To this end, Fraunhofer ISE will act as a committed partner as part of the collaboration with Meyer Burger, leveraging its long-standing expertise in the upscaling of PV production processes and the production and certification of modules.”

(Copyright)