Robot dogs help run 'world’s first' unmanned wind farm

Robot dogs working in tandem with drones and other smart technology have meant humans have not set foot in pioneering wind farm for almost a year

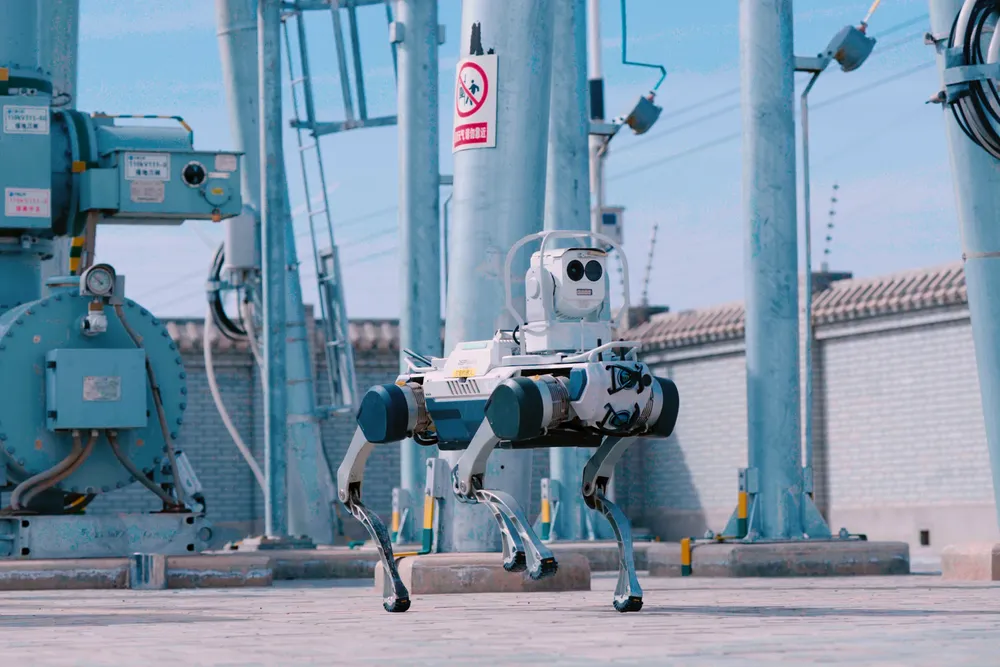

At a remote wind farm high on a wind-swept plateau, a robotic dog stalks around the substation, sniffing out any potential faults – come rain or shine – as its human masters sit in a control centre far away.

It sounds, and quite frankly looks, like something out of science fiction, but this is indeed what has been taking place at a trailblazing wind farm up on the Loess Plateau in northern China since September last year.

This is because the site is a pilot project for what could one day be the future for the sector: unmanned wind farms.

That is when the project completed its “unmanned transformation” and the robot dogs stepped in. It’s not just robot dogs, however. The operations and maintenance system at the site features nearly 300 smart cameras, robots, drones and smart sensors.

This network can cover maintenance tasks across over 5,000 inspection points throughout the facility, said Goldwind.

The data and images that are collected are then sent onto a regional control centre where they can be assessed by staff – in this case at the Litong Maintenance Center 30km away.

Since implementing this “human-machine collaboration,” Goldwind said the site has saved more than 3,000 inspection hours, boosted safety and improved overall workforce efficiency by 27%.

“Robot dogs can complete 353 daily inspection tasks,” it said. “A single drone, powered by algorithms, can cover 3,200 inspection checkpoints, with a margin of mistake under 5%.”

Robot dogs, drones and other devices at the wind farm operate independently even when disconnected from the operations centre, said Goldwind, performing inspections, data analysis, and other tasks according to pre-set algorithms.

This intelligent equipment is not supplied by Goldwind itself. Goldwind’s newest canine employees are an X30 model supplied by Chinese company DEEP Robotics.

The company reported earlier this year how its X30 robot dogs cooperate with drones to conduct inspections twice a day. These inspections of components such as transformers, isolation switches and lightning arresters, take around 80 minutes.

The robot dogs and their autonomous friends instantly sound the alarm in the event of any abnormal readings, says DEEP Robotics.

A product specification for the X30 model says that it can operate in environments of -20°C to 55°C. The 56kg machine can also walk up staircases and can navigate in pitch black.

DEEP Robotics has also deployed its robodogs at facilities such as iron and steel works – where their ability to withstand high temperatures comes in useful – and converter stations.

Goldwind says it has now built other “unmanned” power stations for other Chinese entities, including PowerChina.

China Three Gorges also reports having trialled similar solutions at other wind and solar projects. At one solar farm to adopt autonomous surveillance technologies, the developer reports having saved almost 20,000 working hours.

Niu Pei, an engineer at a Three Gorges Energy Smart Operation Center, described the technology as allowing operation and maintenance personnel to free themselves from “tedious and repetitive daily inspections” and devote more energy to technical innovation.

Or, as Huang Ke, team leader at the Litong Maintenance Center for China Three Gorges, put it: “This is how technology changes our lives.”

(Copyright)