'Two blades or three' | EU-backed floating wind trailblazer targets matching onshore green energy

EXCLUSIVE INTERVIEW | NextFloat project based on X1 Wind platform lays foundations for future units of up to 20MW that aim to compete with all-comers on cost, says strategy chief Joao Neves

A new EU-backed floating wind power project is aiming to pave the way for price competitiveness not only with fixed-bottom offshore arrays but with onshore renewable energy too – and could do it with either innovative two- or conventional three-bladed turbines, according to a senior executive at Spanish sector pioneer X1 Wind.

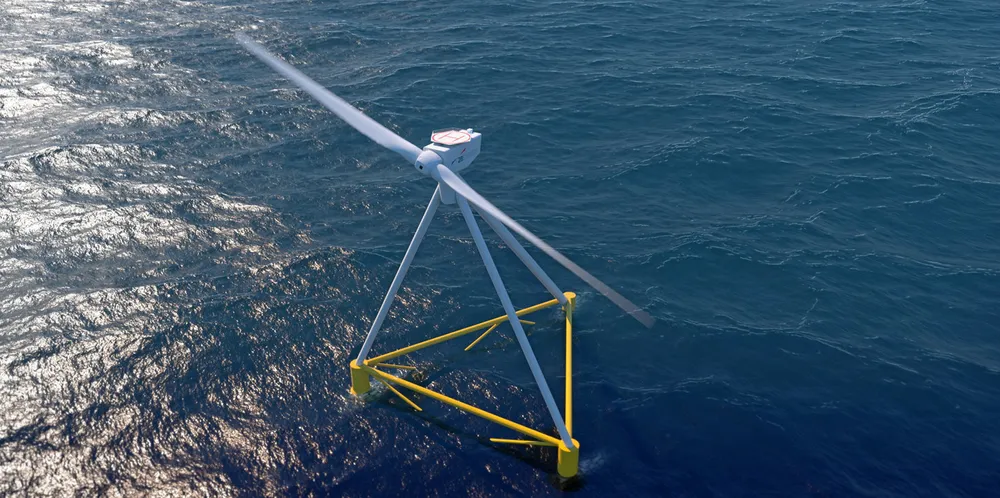

X1 Wind’s PivotBuoy technology is at the heart of the multi-partner NextFloat project, picked by the European Commission to help accelerate the industrialisation of floating wind via a full-scale 6MW prototype in the French Mediterranean, along with associated work on mass-production and deployment.

Joao Neves, director of strategy and business development at X1 Wind, said alongside work on the 6MW unit, the NextFloat team will look to future scale-up to 15MW and later even 20MW ratings.

X1 Wind will also work with project partner DTU (Technical University of Denmark) “to look into the 20MW scale for floaters – to look into the competitiveness of our platform at that scale”.

Designed to ‘weathervane’ with the wind, X1 Wind’s concept hybridises a shallow-draft semisubmersible hull and a tension-leg platform mooring system with a turbine set in a downwind orientation, achieving what its developer claims are the wins of lighter weight, lower steel requirement and smaller seabed footprint.

While not ready yet to put figures on it, Neves claims X1 Wind will be able to deliver “substantial improvements in weight and capex [capital expenditure]” and a “step change” in floating wind as it gets ready to move to the massive scale predicted for the sector.

“To be competitive with solar and onshore wind – that should be our ultimate goal, if we want floating to be deployed at large scale. That’s our ultimate goal once scale is achieved, in the long-term, once these gigawatt parks are in the water. This competitiveness will come not just from our system, but assembling in a serial fashion, deploying in a serial fashion.”

Switch to two blades?

The most eye-catching change for the full-scale NextFloat deployment of the PivotBuoy is the envisaged use of a two-bladed 6MW turbine, rather than the three-bladed Vestas V29 used on the part-scale version.

The NextFloat project consortium includes 2B Energy, a Dutch wind turbine technology developer that has for some years been working on a 6MW two-blader and has an onshore prototype in the Netherlands.

So, does that mean the future of X1 Wind from NextFloat onwards is a two-bladed one – two-blades are often associated with downwind turbine designs – and is there likely any time soon to be the potential to source such a machine at the 15MW scale Neves referred to earlier?

Not necessarily, said Neves: “In this case one of the partners [in NextFloat] is 2B Energy.” But for the longer term, the important factor is the downwind orientation of the turbine.

“We can do both. We are not committed to either two or three blades. The decision in the case of most projects will be the project’s owner – we are happy to adapt ourselves to whatever the owner believes is the best case.”

“From upwind to downwind, the change is minor,” stated Neves,. The supply chain is exactly the same – you don’t need much innovation to turn an upwind into a downwind.”

The X1 Wind executive claimed a downwind turbine “definitely” doesn’t add to cost, and can actually bring advantages and cost savings.

“We’ve spoken to R&D institutes and manufacturers that see the advantages of being downwind. [Down-wind] your blades bend away from the structure, so you can have longer blades, especially in offshore.”

A grant agreement is under negotiation with the European Commission and the project is due to formally kick off in the fourth quarter of the year.